Glass Substrate and High-functional Coating for Perovskite Solar Cells

Support Challenges of Perovskite Solar Cells

Perovskite solar cells have great potential to become future energy conversion devices. However, key challenges such as improvement of power generation ability and long-term stability of perovskite solar cells still exist. We support those challenges with ultra-thin and flexible glass substrate and various high-functional coatings.

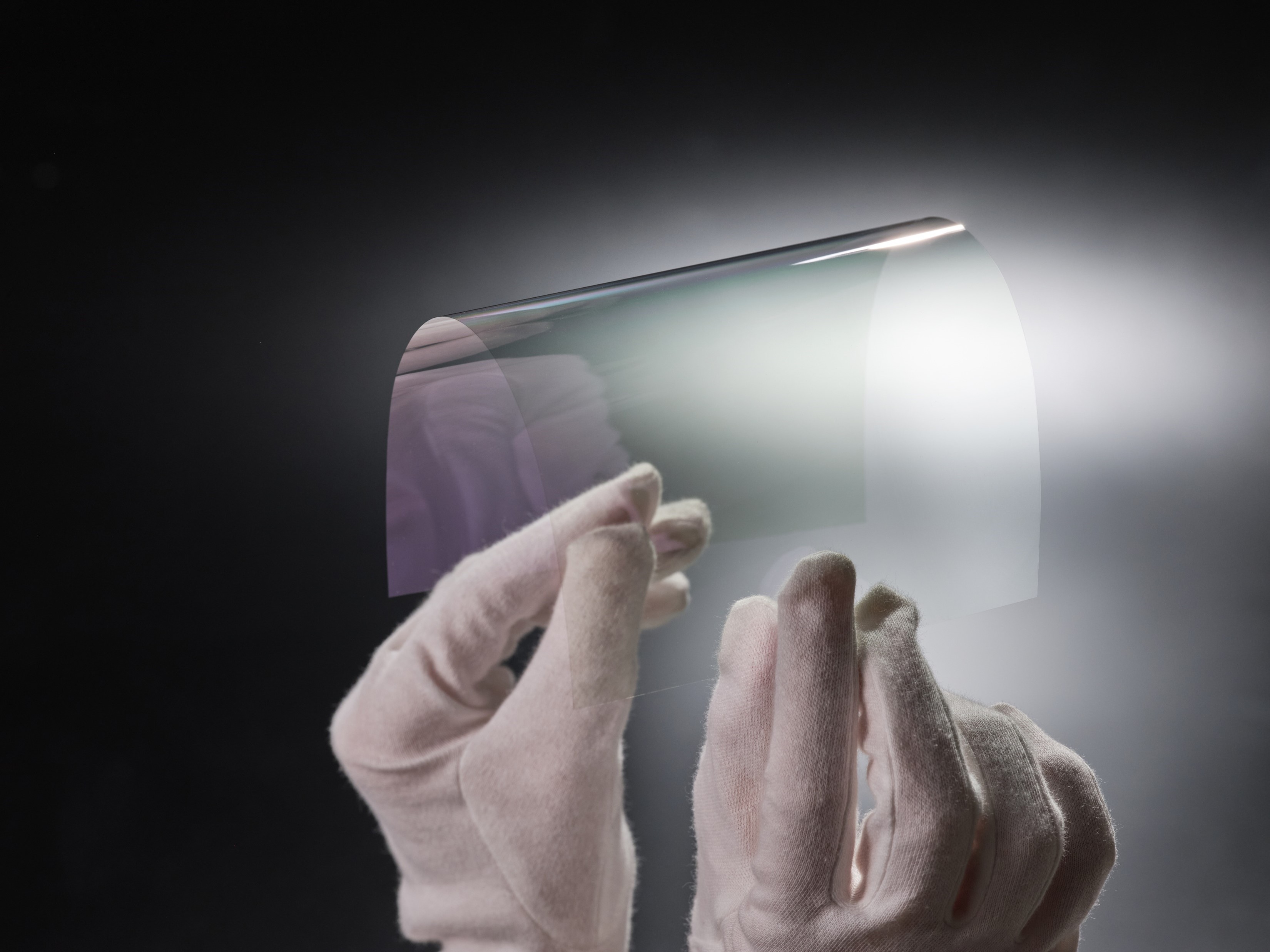

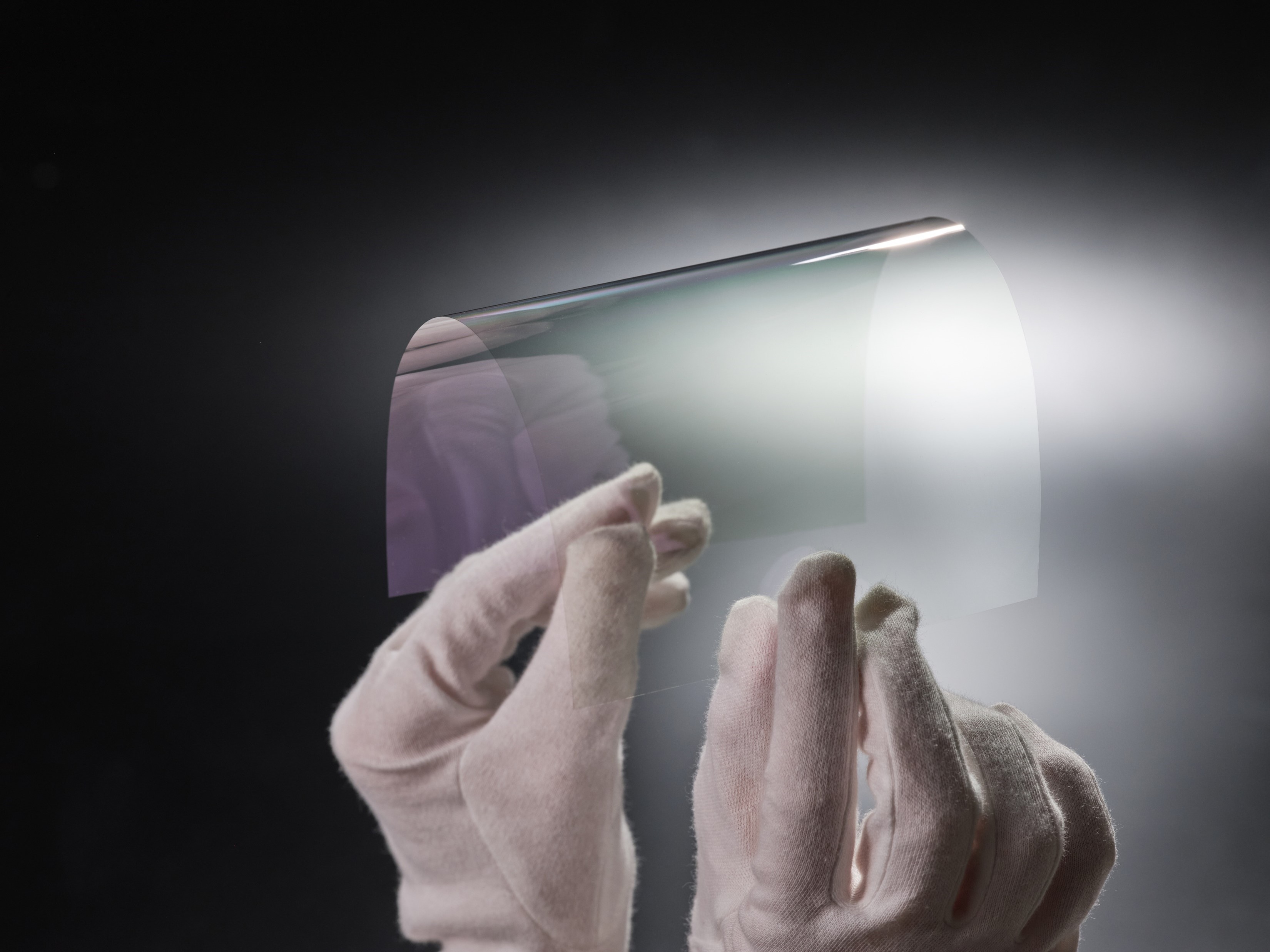

Features of Our Glass Substrate

Our glass substrate has features superior to resin film, as well as excellent flexibility.

Point 01 Gas Barrier Property

Perovskite solar cells can be protected from oxygen and water, which contributes to improvement of long-term stability.

Point 02 High Transparency

Visible light is efficiently transmitted, which contributes to improvement of power generation ability.

Point 03 Heat Resistance

Our glass substrate withstands high temperature, which contributes to broader process condition.

What We Offer Product Information

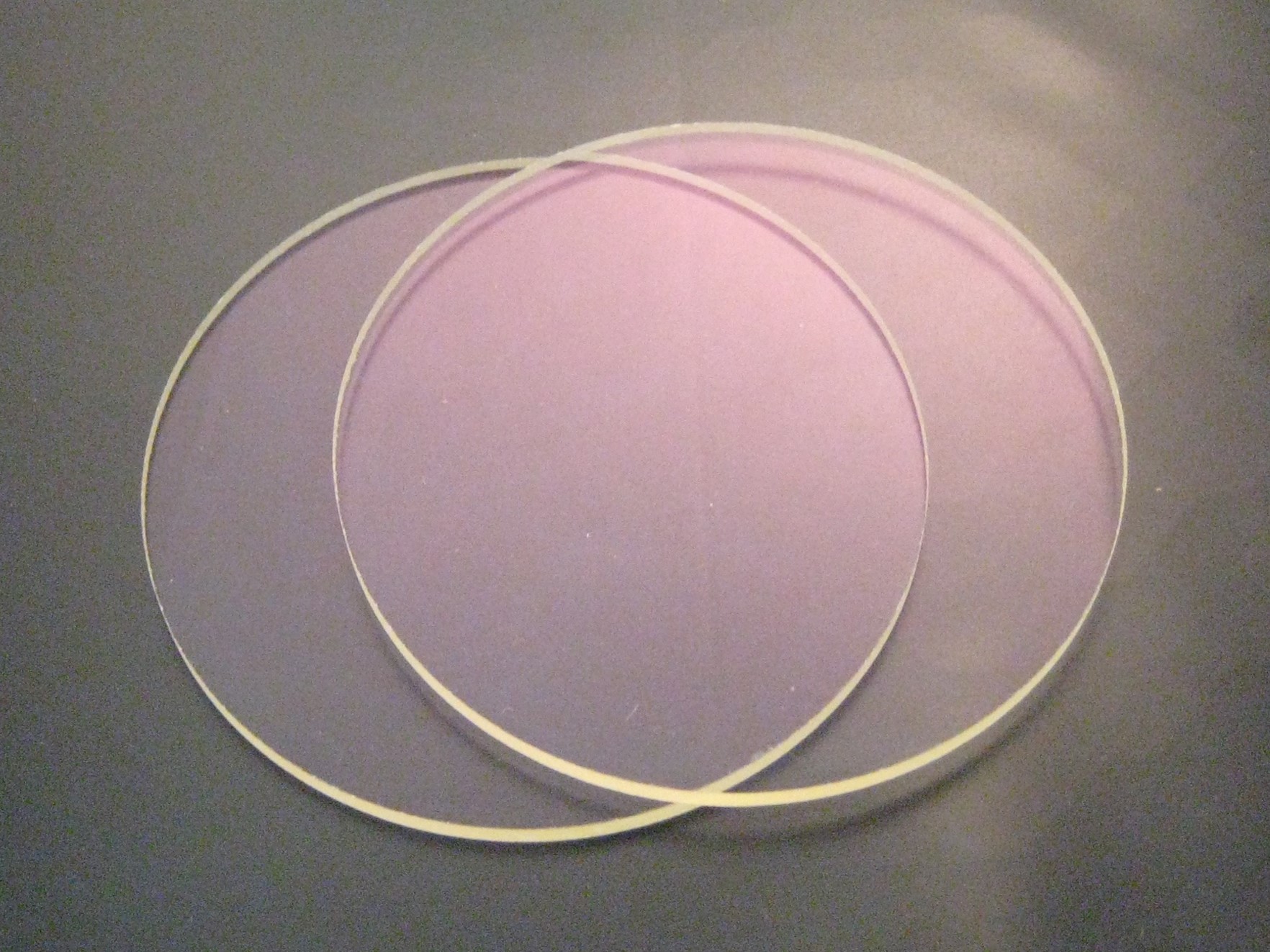

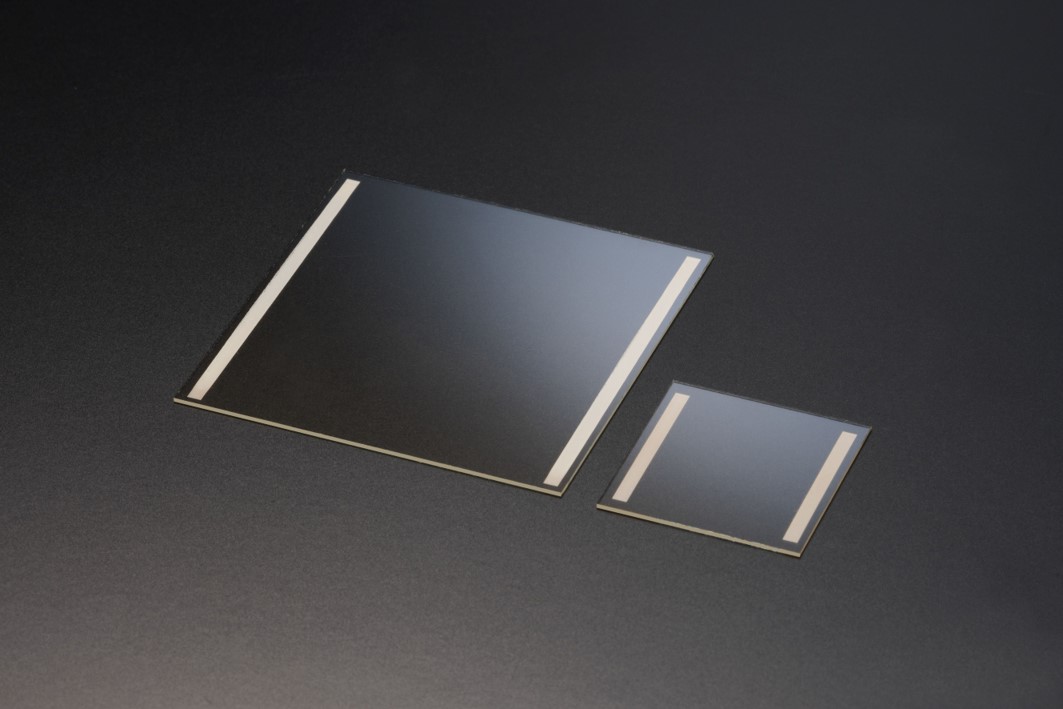

Glass Substrate

We offer two types of glass substrate with thickness down to 30μm, suitable for flexible and/or lightweight perovskite solar cells.

G-LeafTM

G-LeafTM maintains the advantageous features of glass such as gas barrier property, transparency, heat resistance and chemical durability in a film state.

Ultra-thin Glass with UV Shielding Property

Glass substrate which has high shielding property against ultraviolet(UV) rays in addition to the features of G-LeafTM. This glass substrate can protect perovskite solar cells from UV rays.

Coating

We offer various coatings contributing to improvement on long-term stability and power generation ability of perovskite solar cells. By combining our glass substrate and high-functional coating, we offer custom-made product to meet your requirements.

ITO Coating

Transparent electrode is indispensable for perovskite solar cells. Our ITO coating has excellent transparency and electrical conductivity.

UV Cut Coating

Ultraviolet(UV) rays degrade long-term stability of perovskite solar cells. Our UV cut coating effectively protects perovskite solar cells from UV rays.

AR Coating

Anti-reflection(AR) coating contributes to efficient power generation of perovskite solar cells. A wide variety of coating design, from high transmittance to ultra-high transmittance is available.

Other Coatings

We offer other coatings such as metallization with high reflectance(metallized mirror), dielectric coating(half mirror), etc.

Supply Form and Support Process

Our general supply form is glass substrate with coating(optional). Since we have mass production facility of glass substrate and coatings, we can support all stages from R&D to mass production for your required products.

Step 1 Glass Type Selection

We offer two types of glass substrate with various sizes and thicknesses.

・G-LeafTM

・Ultra-thin Glass with UV Shielding Property

Step 2 Coating Design

We can cover all coating process from coating design, coating method selection and test production to meet your requirements.

・ITO Coating

・UV Cut Coating

・AR Coating

・Other Coatings

Step 3 Sample Making/Evaluation

We offer evaluation samples and share the properties/evaluation results with you to develop products which you require.

Step 4 Medium-Scale/Mass Production

We carry out medium-scale production on mass production line and determine specifications for mass production. After starting mass production, we will continue to provide services and support to you.

Contact

Please enter your inquiry using the form below.

Handling of Personal Information:

The personal information you enter will be handled in accordance with our Privacy Policy.

Please read our Privacy Policy and click the "Submit" button after agreeing to the terms of the Privacy Policy.